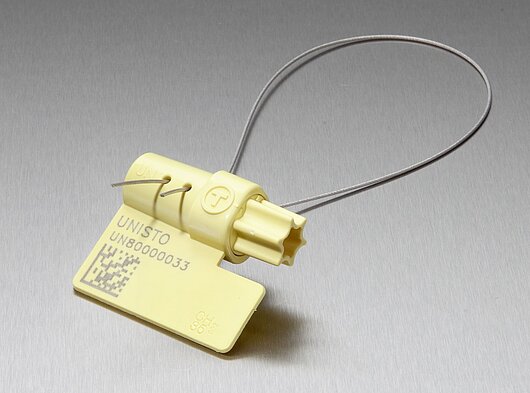

Kännetecken för denna säkerhetsplomb

- Type of Seal

- Special seal according to EN 16882

- Application

- Sealing of motion sensors

- Compact, robust design

- Our system operates in a temperature range of -40° to 135°

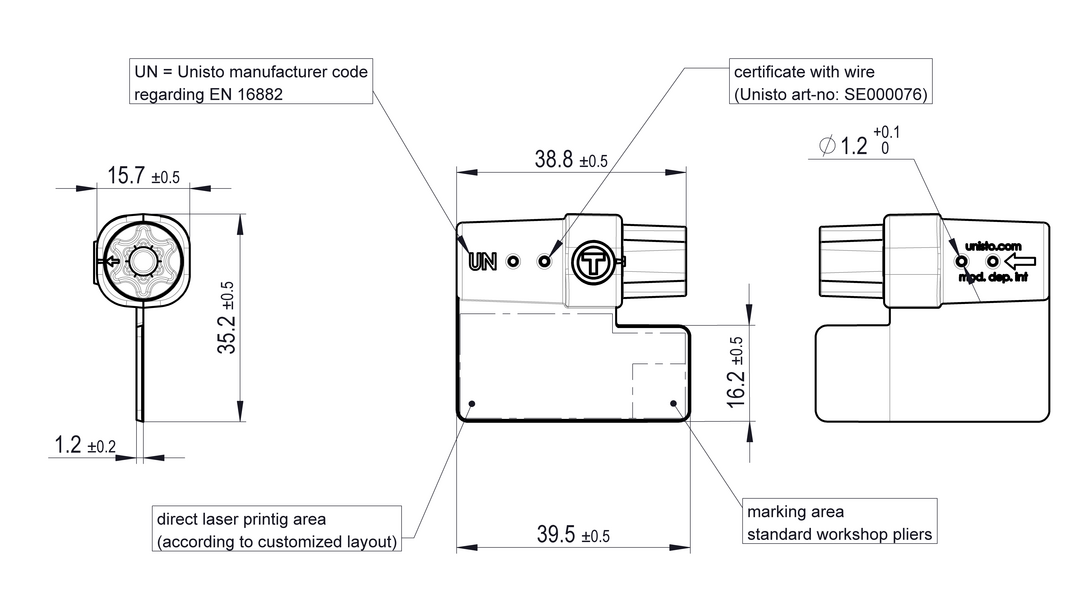

- Flexible adjustment thanks to separately supplied wire

- Various colours for logistics purposes

- Customer name and/or identification number for unique identification

- High quality barcode or Datamarix allows fast and secure data acquisition

- Unique manufacturer identification (database European Commission) Unisto is registered as UN

- With area for the application of a special marking by the workshop

- Certified according to the European standard EN 16882

- The only tachograph seal tested for manipulation by the BAM ( The Bundesanstalt für Materialforschung und -prüfung, Germany). Test procedure according to DIN EN 16882- point 6 - Evidence of tampering. BAM Reference - 5.3/10749/19 - DL19053693

- Material

- Housing and knob: aliphatic polyketone

- Wire (Unisto)

- Plastic-coated stainless steel cable, Ø 0.8 mm, on rolls of 100 m

- Tensile strength (loop)

- Over 50 kg (with Unisto wire)

- Barcode

- Directly lasered: UN + 8 numbers

- Datamatrix

- Direct lasered: UN + 8 numbers

- Customer name/code

- According to customer specifications/requirements

- Embossing field

- For marking by the workshop/garage

- Packaging

- 100 seals per polybag, Polybag in box, boxes of 1'000 pieces.

Unisto Tacho Seal - Security Seal

Sealing of motion sensors. Special seal according to EN 16882 .